I-Silver Tungsten

Imininingwane Yomkhiqizo

Omaka bomkhiqizo

I-Ningbo De-Shin inikeza uhla olugcwele lwe-tungsten esiliva emikhakheni ehlukene yezicelo zezimboni. Kuthatha inqubo yokungena kwe-vacuum ethuthukisiwe futhi yonke imikhiqizo ihlangabezana nombandela we-GB/T8320-2003, ASTM B631.

Inqubo yokukhiqiza:i-powder mix -> pressing –> sintering –> vacuum infiltration –> machining –> QC. Yonke le nqubo yokukhiqiza ilawulwa ngokuqinile yi-QC ukuze kuqinisekiswe ukusebenza kwekhwalithi engcono kakhulu.

Izinzuzo:

1. High conductivity kagesi.

2. High conductivity ezishisayo.

3. Ukuminyana okuphezulu nokufana okuphelele kwe-microstruction yento.

Izicelo:

1. Izinqamuli zesekethe.

2. Izinqamuli zokuvuza komhlaba.

3. Ama-circuit breakers amancane.

4. ukumelana welding electrode.

5. ukugqoka shaft ukumelana

Usayizi wesitoko:

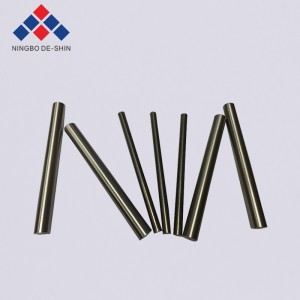

Induku ye-tungsten yesiliva: ububanzi≥0.5mm, ngokuvamile i-1-60mm; ubude≤300mm, ngokuvamile 100, 175, 200, 300mm.

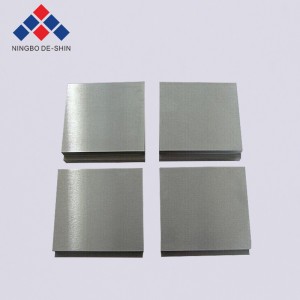

Ibha yesikwele ye-tungsten yesiliva: ukujiya≥1.0mm, ngokuvamile ngu-1-40mm; ubude nobubanzi≤400mm, ngokuvamile 100*200, 200*300, 200*400mm.

| ibanga | Ukwakhiwa Kwekhemikhali (wt%) | Ukuminyana | Ukuqina | Ukungazweli | ||

| Ag | Ukungcola Okuphelele≤ | W | g/cm3 ≥ | HB Kgf/mm2 ≥ | μΩ.cm ≤ | |

| W30/Ag70 | 70±1.5 | 0.5 | Ibhalansi | 11.75 | 75 | 2.3 |

| W40/Ag60 | 60±1.5 | 0.5 | Ibhalansi | 12.40 | 85 | 2.6 |

| W50/Ag50 | 50±2.0 | 0.5 | Ibhalansi | 13.15 | 105 | 3.0 |

| W55/Ag45 | 45±2.0 | 0.5 | Ibhalansi | 13.55 | 115 | 3.2 |

| W60/Ag40 | 40±2.0 | 0.5 | Ibhalansi | 14.00 | 125 | 3.4 |

| W65/Ag35 | 35±2.0 | 0.5 | Ibhalansi | 14.50 | 135 | 3.6 |

| W70/Ag30 | 30±2.0 | 0.5 | Ibhalansi | 14.90 | 150 | 3.8 |

| W75/Ag25 | 25±2.0 | 0.5 | Ibhalansi | 15.40 | 165 | 4.2 |

| W80/Ag20 | 20±2.0 | 0.5 | Ibhalansi | 16.10 | 180 | 4.6 |

| W85/Ag15 | 15±2.0 | 0.5 | Ibhalansi | 16.70 | 195 | 5.0 |