Ejò Tungsten

Alaye ọja

ọja Tags

Ningbo De-Shin nfunni ni kikun ti tungsten Ejò (6 ~ 50wt.% Cu) fun awọn aaye ohun elo ile-iṣẹ oriṣiriṣi. O gba ilana infiltration igbale igbale ti ilọsiwaju ati pe gbogbo awọn ọja ni ibamu pẹlu ami-ẹri GB/T 8320-2003, ASTM B 702-93 (Ti a fọwọsi 2004). Tungsten Ejò jẹ pseudo-alloy ati pe o ni agbara resistance resistance ti tungsten ati ina elekitiriki giga ti Ejò.

Ilana iṣelọpọ:powder mix –> tẹ –> sintering –> igbale infiltration –> machining –> QC. Gbogbo ilana iṣelọpọ yii jẹ iṣakoso ti o muna nipasẹ QC lati rii daju iṣẹ didara ti o dara julọ.

Awọn anfani:

1. Giga arc resistance ni idapo pelu itanna eleto to dara.

2. Ga gbona iba ina elekitiriki.

3. Low gbona imugboroosi.

Awọn ohun elo:

1. Arcing awọn olubasọrọ ati awọn olubasọrọ vaccum ni ga ati alabọde foliteji breakers tabi vaccum interruptors.

2. Electrodes ni ina sipaki ogbara gige ero.

3. Ririnkiri ọja! Ooru ge bi awọn eroja itutu palolo ti awọn ẹrọ itanna ati awọn ohun elo apoti Itanna.

4. Electrodes fun resistance alurinmorin.

Iwọn iṣura:

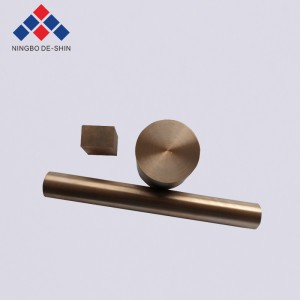

Ọpa tungsten Ejò: diamita≥0.5mm; ipari≤300mm.

Ejò tungsten awo: sisanra≥1.0mm; ipari & iwọn≤300mm.

| ite | Iṣọkan Kemikali (wt%) | iwuwo | Lile | Resistivity | IACS | Titẹ Agbara | ||

| Cu | Lapapọ Awọn ohun aimọ≤ | W | g/cm3 ≥ | HB Kgf/mm2 ≥ | μΩ.cm ≤ | % ≥ | MPa ≥ | |

| W50/Cu50 | 50± 2.0 | 0.5 | Iwontunwonsi | 11.85 | 115 | 3.2 | 54 | – |

| W55/Cu45 | 45± 2.0 | 0.5 | Iwontunwonsi | 12.30 | 125 | 3.5 | 49 | – |

| W60/Cu40 | 40± 2.0 | 0.5 | Iwontunwonsi | 12.75 | 140 | 3.7 | 47 | – |

| W65/Cu35 | 35± 2.0 | 0.5 | Iwontunwonsi | 13.30 | 155 | 3.9 | 44 | – |

| W70/Cu30 | 30± 2.0 | 0.5 | Iwontunwonsi | 13.80 | 175 | 4.1 | 42 | 790 |

| W75/Cu25 | 25± 2.0 | 0.5 | Iwontunwonsi | 14.50 | 195 | 4.5 | 38 | 885 |

| W80/Cu20 | 20± 2.0 | 0.5 | Iwontunwonsi | 15.15 | 220 | 5.0 | 34 | 980 |

| W85/Cu15 | 15± 2.0 | 0.5 | Iwontunwonsi | 15.90 | 240 | 5.7 | 30 | 1080 |

| W90/Cu10 | 10± 2.0 | 0.5 | Iwontunwonsi | 16.75 | 260 | 6.5 | 27 | 1160 |