Tungsten ọla ọcha

Nkọwa ngwaahịa

Mkpado ngwaahịa

Ningbo De-Shin na-enye tungsten ọlaọcha zuru oke maka mpaghara ngwa ụlọ ọrụ dị iche iche. Ọ na-ewe usoro ntinye oghere oghere dị elu yana ngwaahịa niile na-agbaso ụkpụrụ GB/T8320-2003, ASTM B631.

Usoro mmepụta:ntụ ntụ mix -> ịpị -> sintering -> agụụ infiltration -> machining -> QC. Usoro mmepụta a niile bụ nke QC na-achịkwa nke ọma iji hụ na arụmọrụ kacha mma.

Uru:

1. Igwe ọkụ eletrik dị elu.

2. High thermal conductivity.

3. High njupụta na zuru okè uniformity microstruction nke ihe onwunwe.

Ngwa:

1. Ndị na-agbaji sekit.

2. Ndị na-agbaji mmiri n'ụwa.

3. Obere sekit breakers.

4. eguzogide ịgbado ọkụ electrode.

5. eyi osisi mgbochi

Nha ngwaahịa:

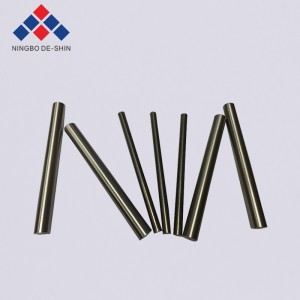

mkpanaka tungsten ọlaọcha: dayameta≥0.5mm, na-abụkarị 1-60mm; ogologo≤300mm, na-emekarị 100, 175, 200, 300mm.

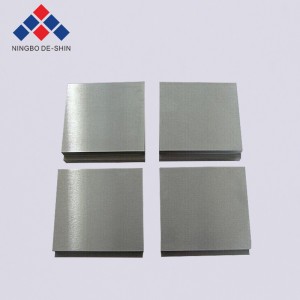

Silver tungsten square mmanya: ọkpụrụkpụ≥1.0mm, na-emekarị 1-40mm; ogologo & obosara≤400mm, na-emekarị 100 * 200, 200 * 300, 200 * 400mm.

| ọkwa | Ngwakọta kemịkalụ (wt%) | Njupụta | Isi ike | Nguzogide | ||

| Ag | Mkpokọta adịghị ọcha≤ | W | g/cm3 ≥ | HB Kgf/mm2 ≥ | μΩ.cm ≤ | |

| W30/Ag70 | 70± 1.5 | 0.5 | Nhazi | 11.75 | 75 | 2.3 |

| W40/Ag60 | 60± 1.5 | 0.5 | Nhazi | 12.40 | 85 | 2.6 |

| W50/Ag50 | 50± 2.0 | 0.5 | Nhazi | 13.15 | 105 | 3.0 |

| W55/Ag45 | 45±2.0 | 0.5 | Nhazi | 13.55 | 115 | 3.2 |

| W60/Ag40 | 40± 2.0 | 0.5 | Nhazi | 14.00 | 125 | 3.4 |

| W65/Ag35 | 35± 2.0 | 0.5 | Nhazi | 14.50 | 135 | 3.6 |

| W70/Ag30 | 30± 2.0 | 0.5 | Nhazi | 14.90 | 150 | 3.8 |

| W75/Ag25 | 25± 2.0 | 0.5 | Nhazi | 15.40 | 165 | 4.2 |

| W80/Ag20 | 20± 2.0 | 0.5 | Nhazi | 16.10 | 180 | 4.6 |

| W85/Ag15 | 15± 2.0 | 0.5 | Nhazi | 16.70 | 195 | 5.0 |