EDM Taping Electrode

Product Detail

Product Tags

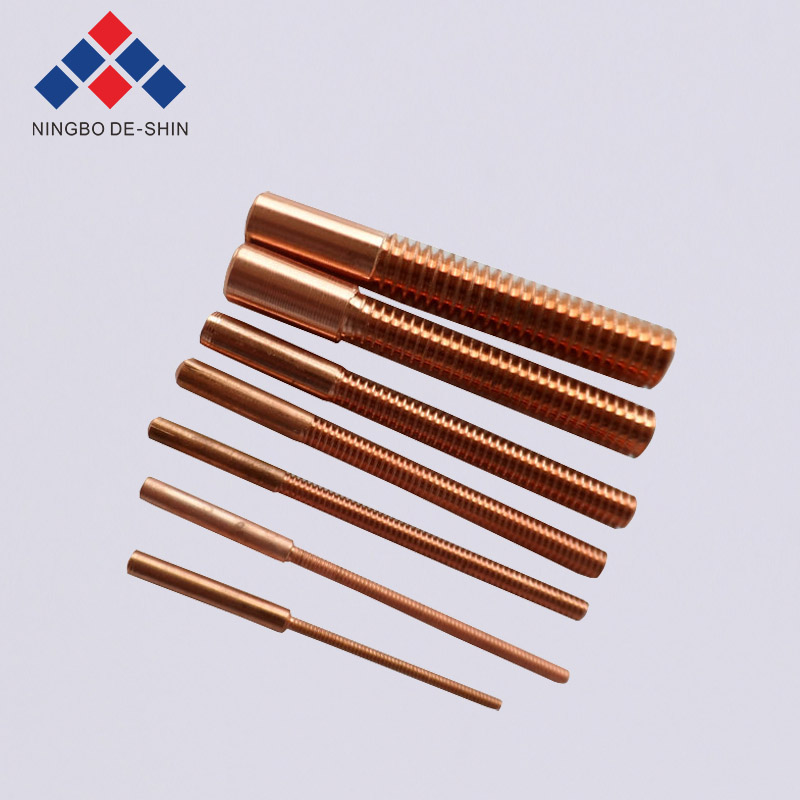

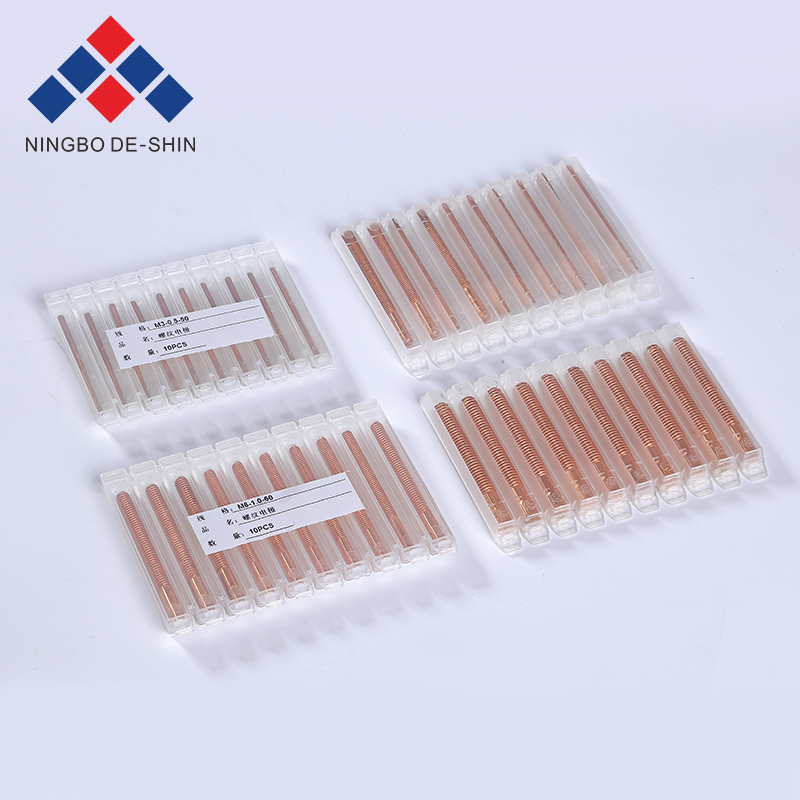

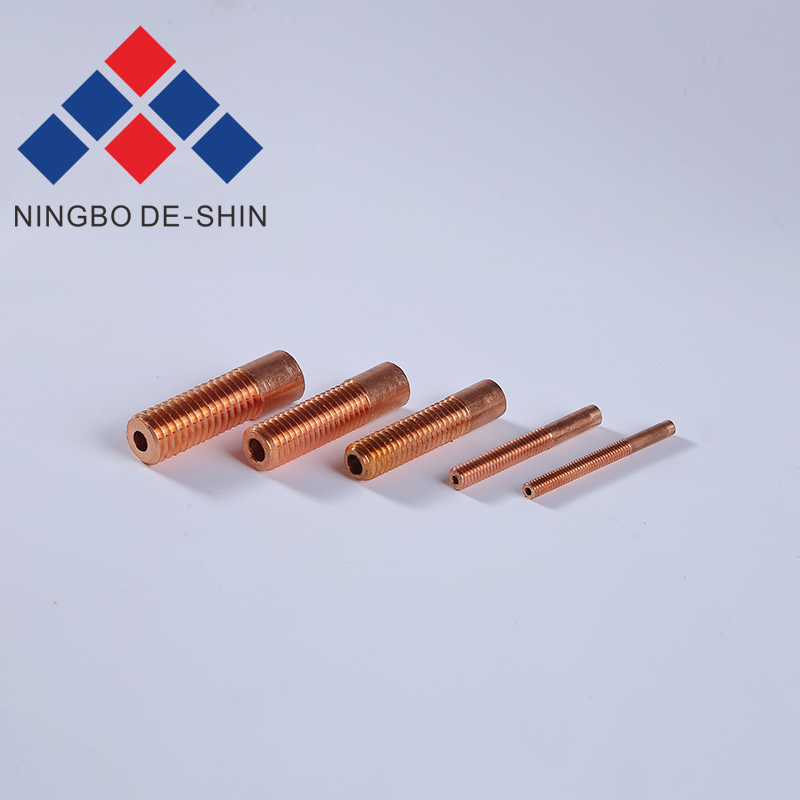

Ningbo De-Shin offers a complete line of threaded taping electrode for EDM machining process. The products offered has the property of uniform thread, pure & consistent color with stable good quality. It can be used to machining all conductive materials like C45C, SKD11, white steel, tungsten steel, copper products, aluminium, etc.

Material available: copper(Cu), copper tungsten(WCu)(such as W70, W75, W80, W85, etc).

Specification: M1.2, M1.6, M2, M2.5/2.6, M3, M3.5, M4, M5, M6, M7, M8, M9, M10, M12, M14, M16, M18, M20, M22, M24, M27, M30…

Pitch: refer to our standard below or can be designed according to yours.

Thread Length: 35mm, 40mm, 45mm, 50mm, 60mm, etc.

Electrode Length: 45mm, 50mm, 55mm, 60mm, 75mm, etc.

| spec | pitch (mm) |

shank dia. (mm) |

thread dia. ±0.1(mm) |

thread length ±2(mm) |

total length ±2(mm) |

thread length ±2(mm) |

total length ±2(mm) |

thread length ±2(mm) |

total length ±2(mm) |

| M1.2 | 0.25 | 0.8 | 0.8 | 8 | 20 | ||||

| M1.6 | 0.35 | 1.2 | 1.2 | 15 | 45 | ||||

| M2.0 | 0.4 | 1.5 | 1.5 | 20 | 45 | ||||

| M2.5/2.6 | 0.45 | 1.8 | 1.8 | 25 | 45 | ||||

| M3 | 0.5 | 2.2 | 2.2 | 35 | 55 | 40 | 60 | 50 | 75 |

| M3.5 | 0.6 | 3.0 | 2.8 | 35 | 55 | 40 | 60 | 50 | 75 |

| M4 | 0.7 | 3.0 | 3.0 | 35 | 55 | 40 | 60 | 50 | 75 |

| M5 | 0.8 | 4.0 | 4.0 | 35 | 55 | 40 | 60 | 50 | 75 |

| M6 | 1 | 5.0 | 4.8 | 35 | 55 | 40 | 60 | 50 | 75 |

| M7 | 1 | 6.0 | 5.8 | 35 | 55 | 40 | 60 | 50 | 75 |

| M8 | 1.25 | 8.0 | 6.5 | 35 | 55 | 40 | 60 | 50 | 75 |

| M9 | 1.25 | 8.0 | 7.7 | 35 | 55 | 40 | 60 | 50 | 75 |

| M10 | 1.5 | 8.0 | 8.0 | 35 | 55 | 40 | 60 | 50 | 75 |

| 10 | 8.5 | 35 | 55 | 40 | 60 | 50 | 75 | ||

| M12 | 1.75 | 10 | 10 | 35 | 55 | 40 | 60 | 50 | 75 |

| M14 | 2 | 12 | 11.7 | 35 | 55 | 40 | 60 | 50 | 75 |

| M16 | 2 | 14 | 13.7 | 35 | 55 | 40 | 60 | 50 | 75 |

| M18 | 2.5 | 16 | 15.2 | 35 | 55 | 40 | 60 | 50 | 75 |

| M20 | 2.5 | 18 | 17.2 | 35 | 55 | 40 | 60 | 50 | 75 |

| M22 | 2.5 | 20 | 19.2 | 35 | 55 | 40 | 60 | 50 | 75 |

| M24 | 3 | 22 | 20.6 | 35 | 55 | 40 | 60 | 50 | 75 |

| M27 | 3 | 24 | 23.6 | 35 | 55 | 40 | 60 | 50 | 75 |

| M30 | 3.5 | 26 | 26 | 35 | 55 | 40 | 60 | 50 | 75 |

prev

next